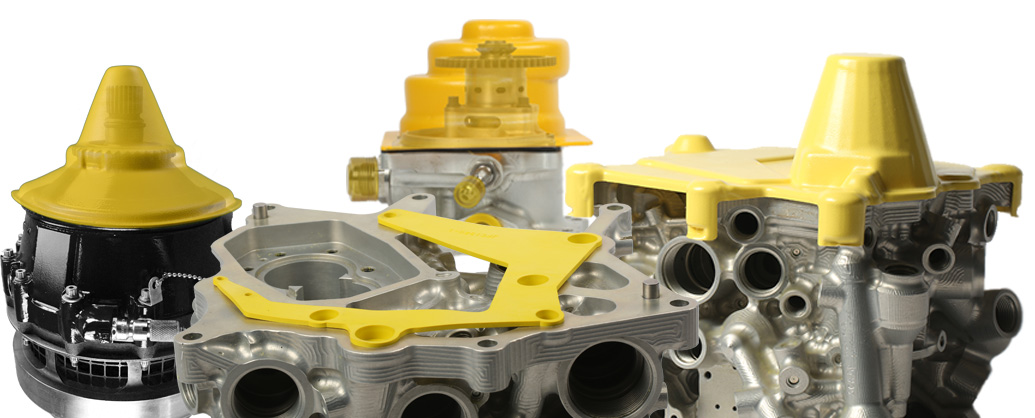

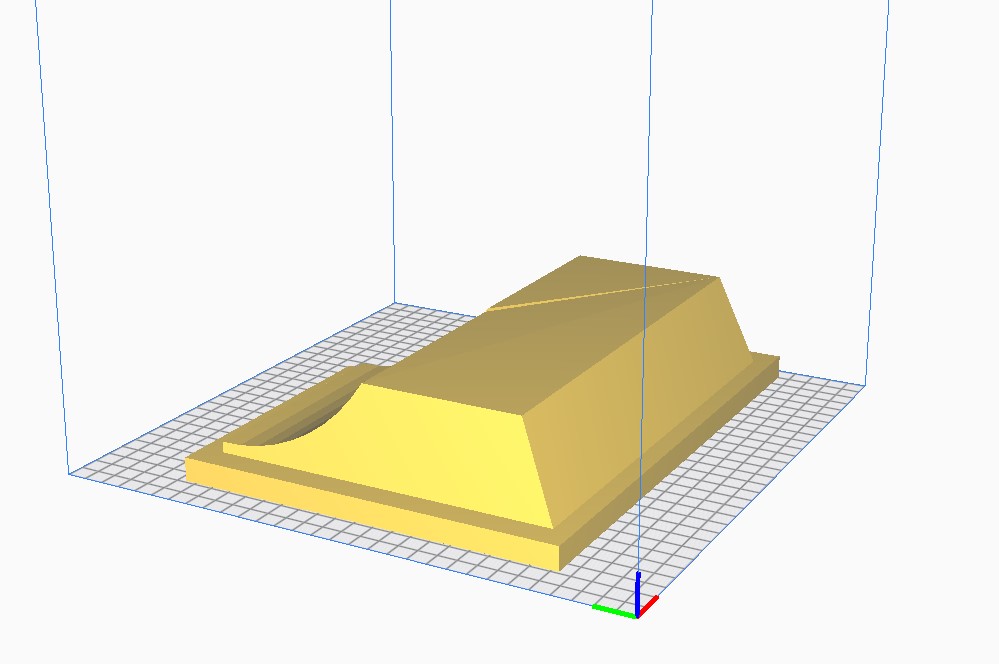

Overview of Ace Technical Plastics

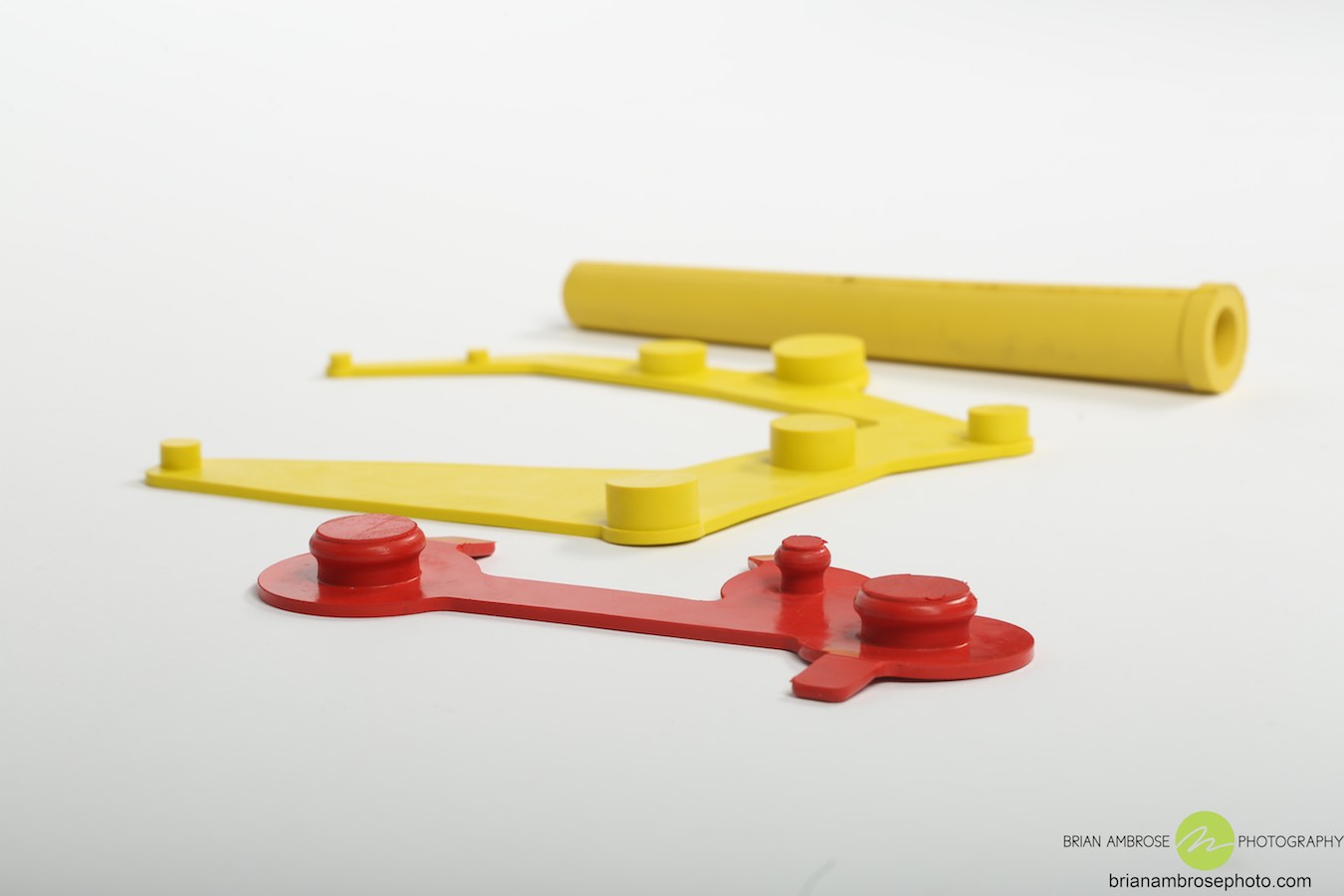

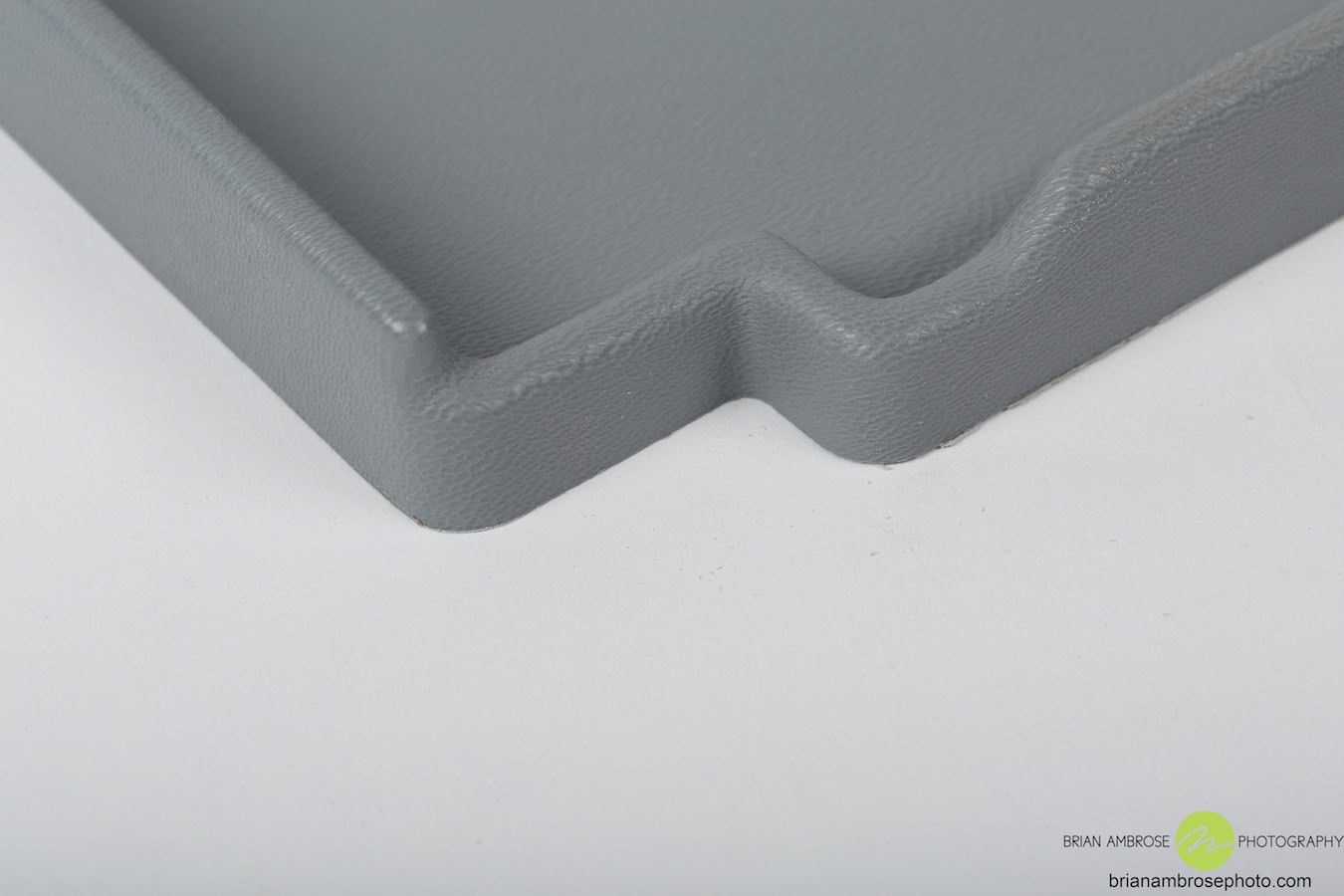

Ace Technical Plastics is specialist in vacuum thermoforming and plastics fabrication. We are also an industry leader in FOD protection and kitting. As a manufacturer, we employ our expertise to manufacture and design creative solutions to solve some of our clients most unusual challenges.

AS9100D & ISO9001:2015 Certified QMS

Click to verify our AS9100 certificate. – Link to ASR Website