Your cart is currently empty!

Overview of Ace Technical Plastics

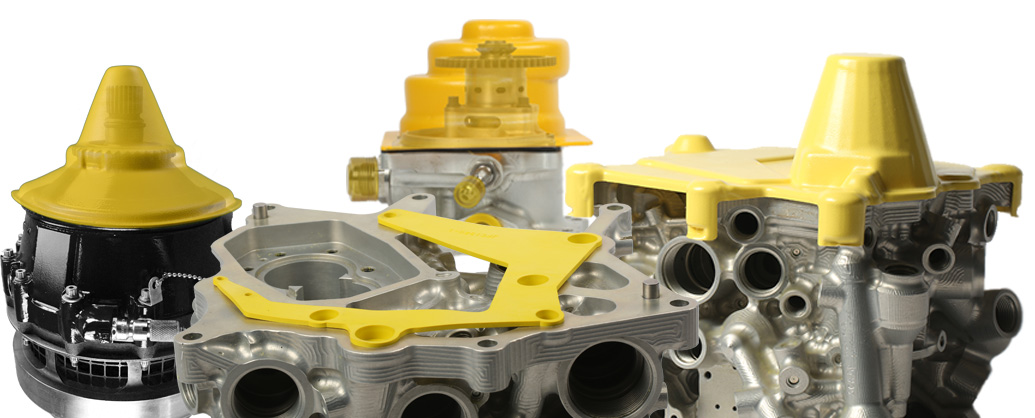

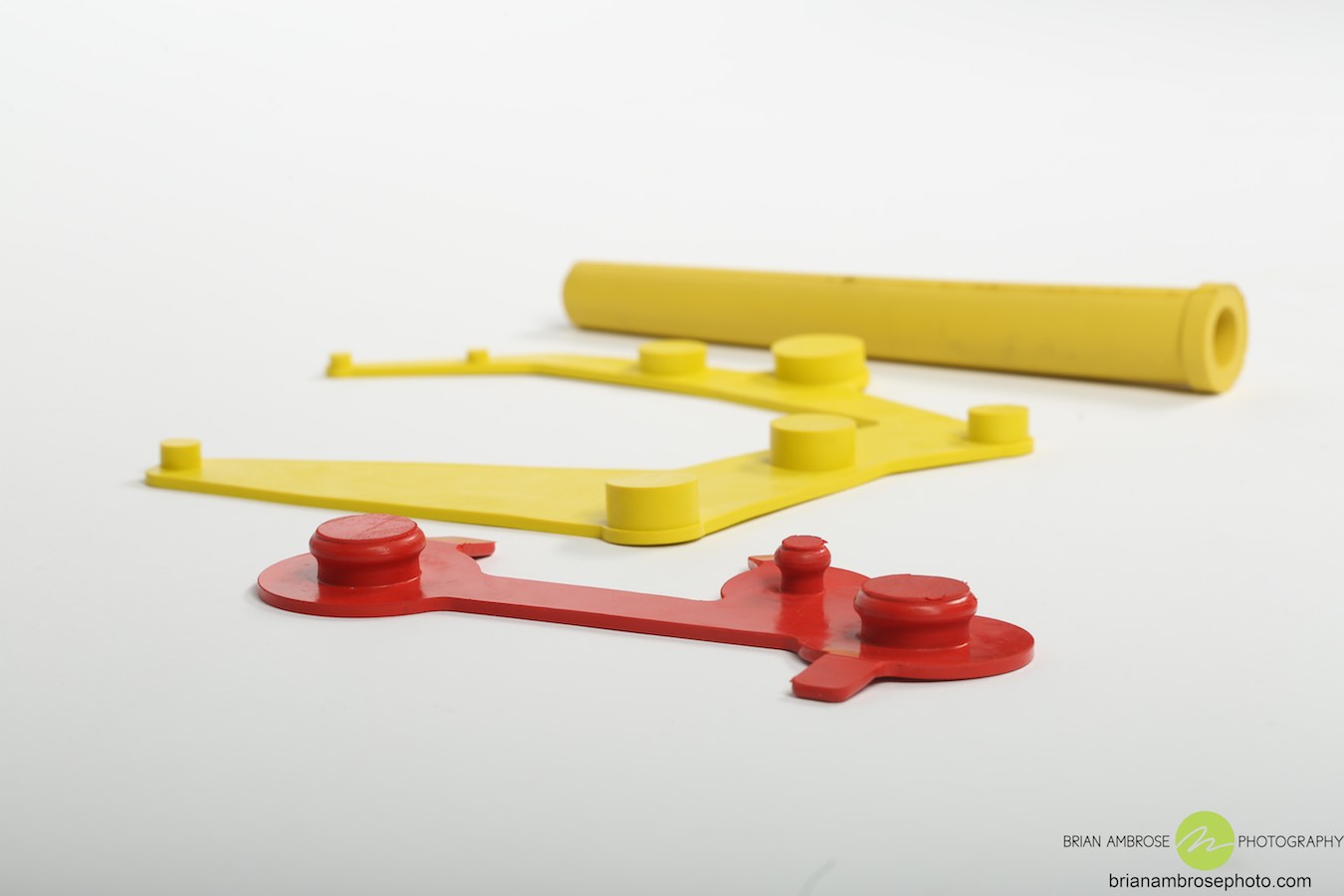

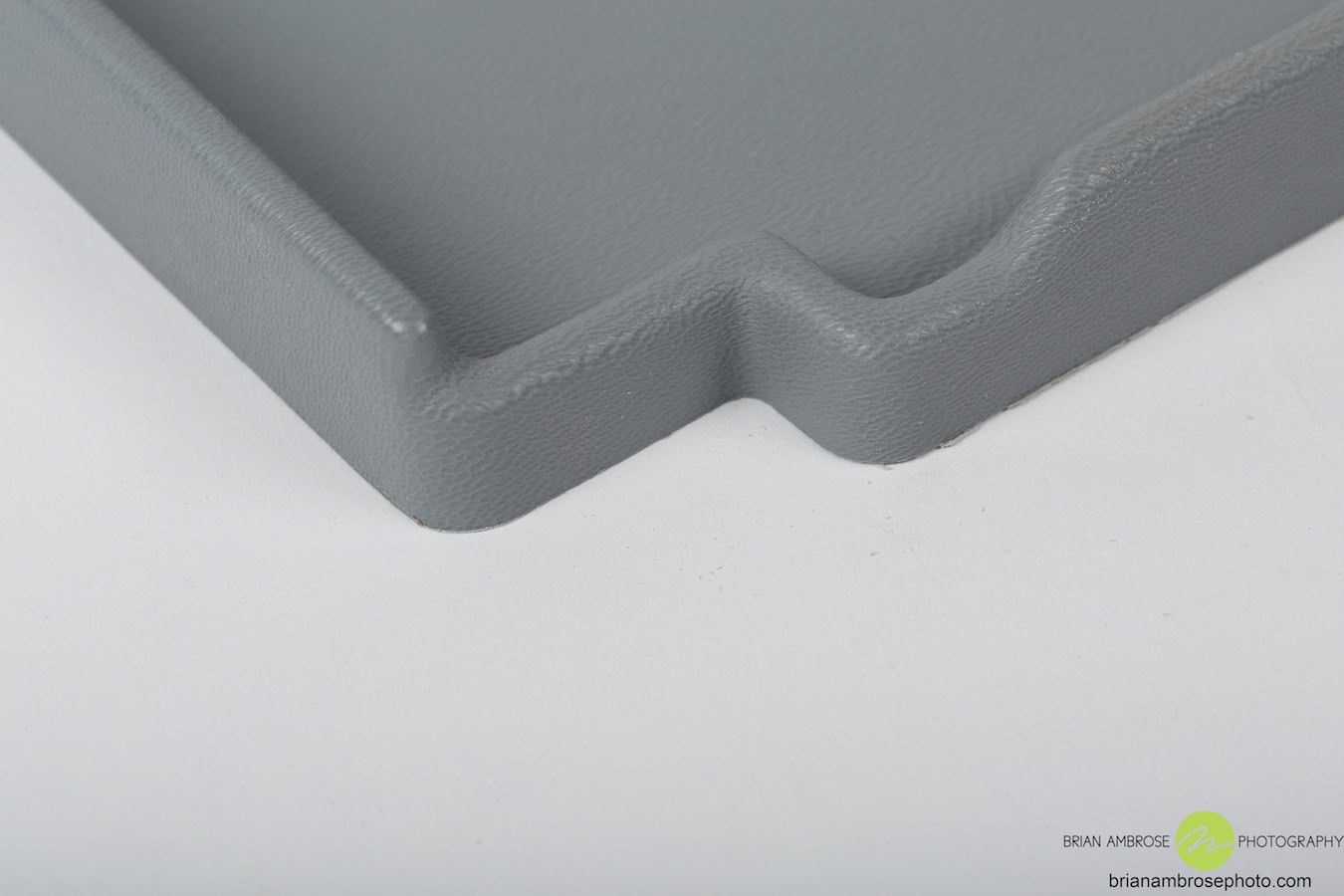

Ace Technical Plastics is specialist in vacuum thermoforming and plastics fabrication. We are also an industry leader in FOD protection and kitting. As a manufacturer, we employ our expertise to manufacture and design creative solutions to solve some of our clients most unusual challenges.

AS9100D & ISO9001:2015 Certified QMS

Click to verify our AS9100 certificate. – Link to ASR Website